8030 – Fully Automatic Twin Spindle Saw

8030 - High end fully automatic twin spindle saw, packed with features and benefits. Up to 12”...

Read more >

Hard bond for soft material.

The Nickel binder provides longer dicing blade life and lower wear rate.

Together with the abrasive makes Nickel-bond Blades a perfect choice for soft material applications such as: PCB, Silicon and BGA

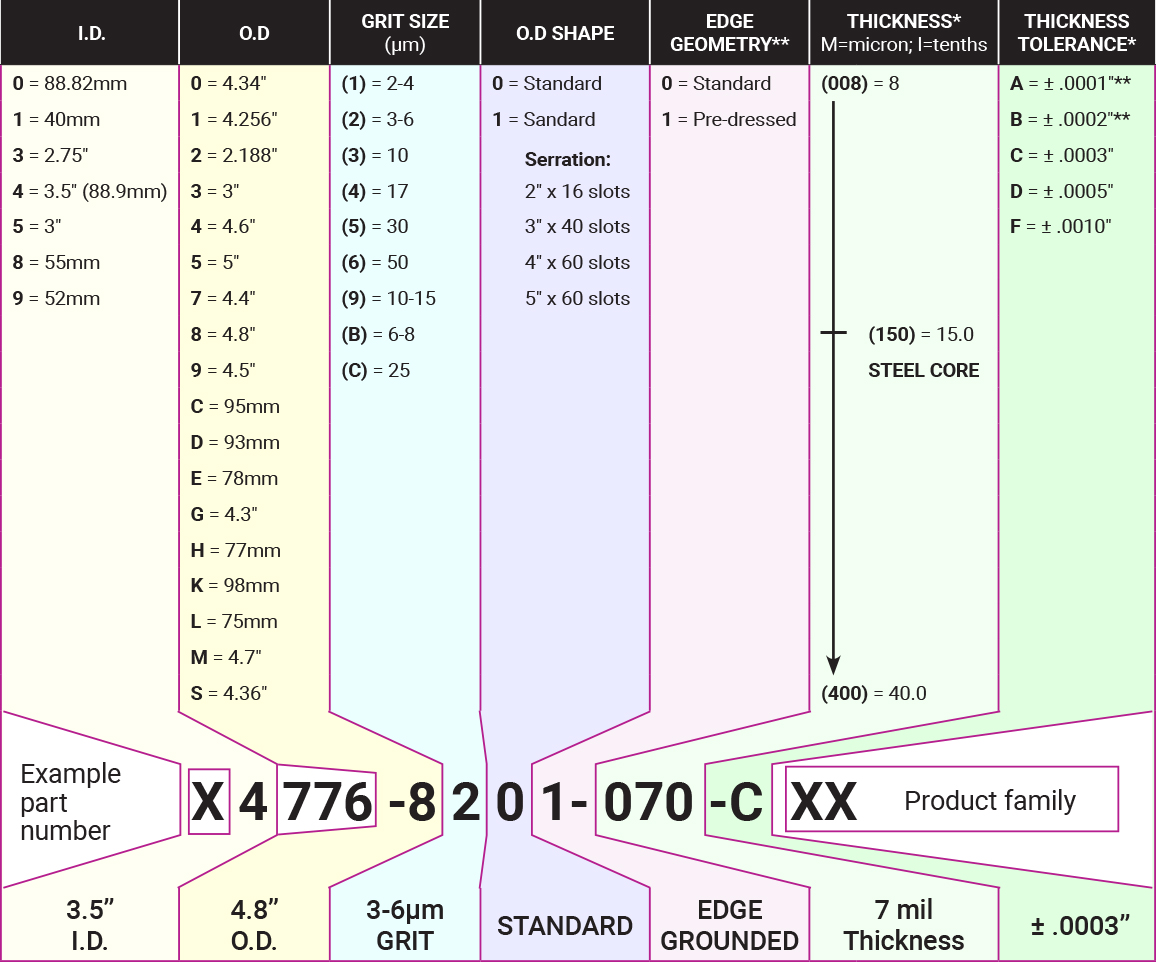

From 50 µm (2 mil) to 300µm (12 mil)

From 3 µm to 50 µm

Serrations available for Nickel dicing blades as well as for various edge shapes

| Diamond grit size (µm) | Product | Material | Matrix |

|---|---|---|---|

| 30 up to 50 | Ceramic / Capacitors | Green Ceramic | BLB/BL0 |

| 10 up to 30 | PCB / LED Package | FR4 / Epoxy & Cu | BLZ, BLV, BLT |

| 6-8 up to 10 | Medical Ultrasound Sensors | PZT | A0T |

| 2-4 up to 4-8 | IC's | Silicon | Hub blades |

Best suited for applications such as Green Ceramic, BGA (Tape process).

Only the rim (the cutting edge of the blade) is composed of nickel and diamonds

from 300µm to 750µm

From 10µm to 70µm

Serrations available for Steel Core Nickel dicing blades as well as for various edge shapes

| Diamond grit size (µm) | Product | Material | Matrix |

|---|---|---|---|

| 30 up to 50 | Ceramic / Capacitors | Green Ceramic | BLB/BL0 |

| 10 up to 30 | PCB / LED Package | FR4 / Epoxy & Cu | BLZ, BLV, BLT |

| 6-8 up to 10 | Medical Ultrasound Sensors | PZT | A0T |

| 2-4 up to 4-8 | IC's | Silicon | Hub blades |

Copyright © ADT – Advanced Dicing Technologies, 2025

Design Maxmark